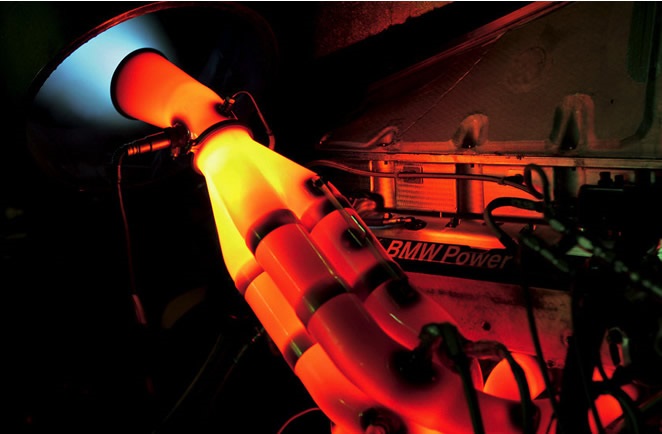

ENGINE TESTING

- CONSULTANCY -

|

|

Thanks to the collaboration with several engine test beds located throughout Europe ,

We can also provide assistance for all facilities already equipped with test rooms,

-Set the layout of the test bed to perform specific tests |

|

We can provide support for all of the following activities:

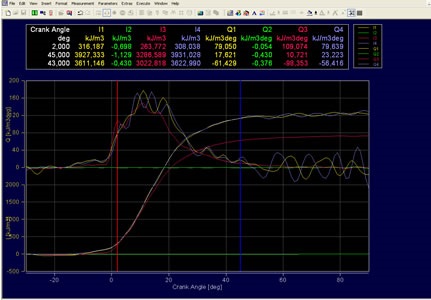

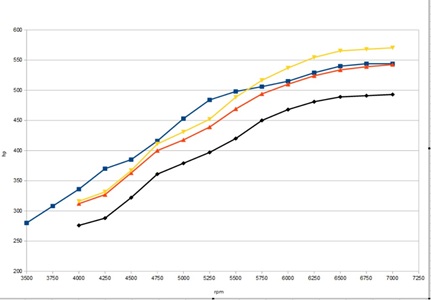

- Validation of engines with verification of characteristic curves |

|

|

It is possible to test engines using the following facilities: |

|

Automotive engine test bed: It is possible to test any endothermic engine, depending on the request it is possible to perform tests in test beds equipped with water brake for engines over 1000hp, test beds with eddy current brakes for power up to 900 hp and test beds with dynamic brakes to perform particular engine simulations. |

|

Test bed for motorcycle engines: It is equipped with a eddy current brake for maximum powers of 300 hp. |

|

Chassis dynamometer and Hub dyno:

4WD Braked chassis dyno can be used for power up to 1000hp, It is also possible to perform tests using a Hub dyno directly at the wheel hubs. |

|

Flowbench / Camshaft test bench:

It is possible to perform tests using a flow bench also for supercharged versions, useful for parameterization and characterizing the |